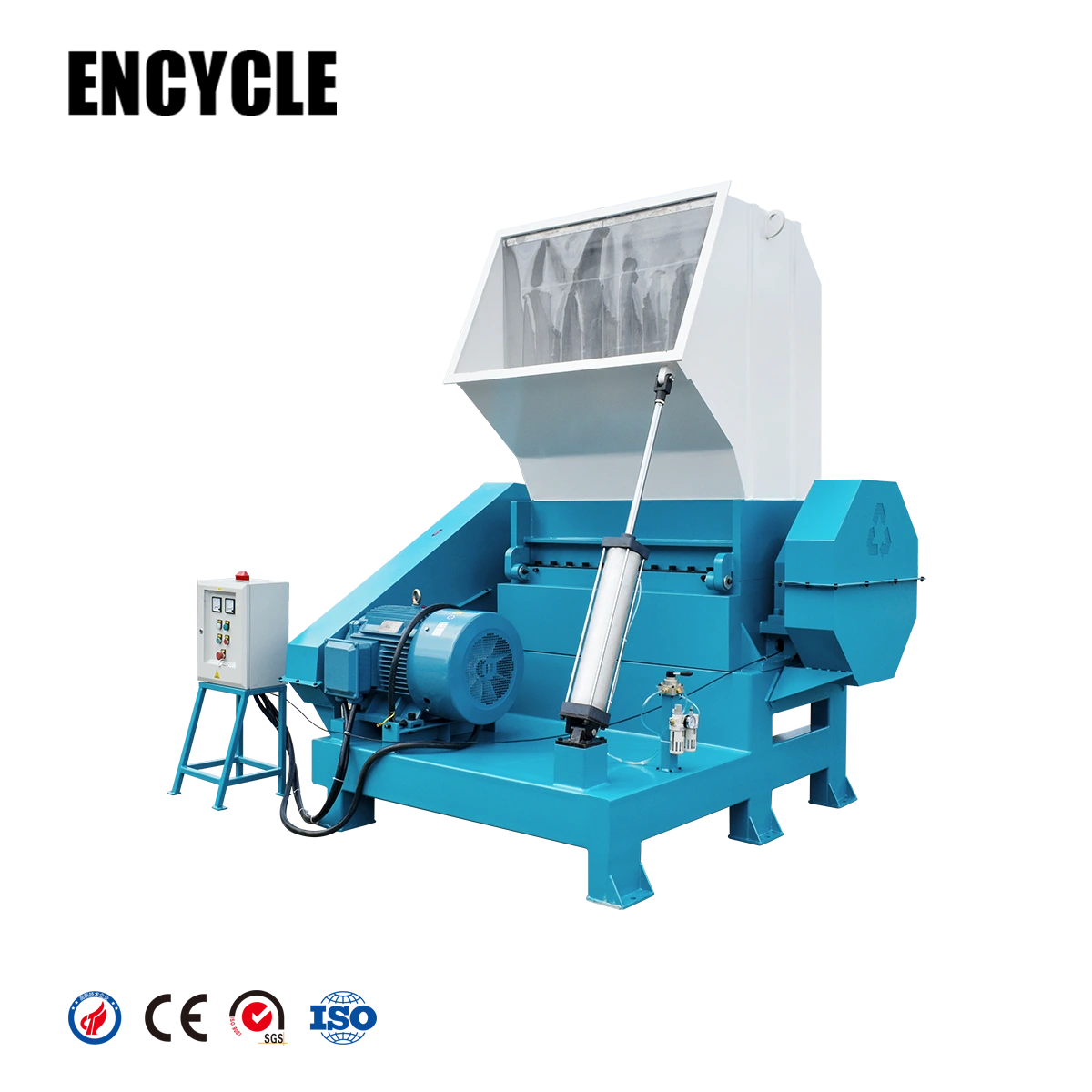

Waste Plastic Crusher Shredder Machine

Plastic crusher is a machine that shreds and breaks materials into particles or sheets of different sizes.

Plastic crushers can ensure smooth crushing of plastic and rubber products of different shapes,

such as ABS, PC, PET, PVC. Plastic crushers have high rotational speed and sharp blades,

usually used for fine crushing.

Crusher Machine Product Details

By replacing the appropriate screen and adjusting the blade spacing, it can also be used to crush PVC/PP/PE film,

PET bottles, plastic flakes, and other types of plastic waste.

Film Crusher Machine

The plastic film crusher incorporates advanced domestic and international technologies, boasts a rational design, and has been continuously refined through repeated testing. It features lightweight, low energy consumption, high quality, long life, and easy cleaning.

The plastic film crusher is suitable for crushing defective plastic products such as polystyrene, polypropylene, nylon, and those produced by injection molding machines and extruders.

Advantages

1. Sturdy construction, easy operation, low power consumption, and durability.

2. Made of high-quality steel, the crusher blades, in particular, are designed to withstand harsh, continuous use.

3. Available flat and claw blades, as well as screens of varying aperture sizes, meet various needs.

4. A double-layer noise reduction design reduces noise output.

5. A power-off protection system ensures equipment safety.

6. Easy to clean and maintain: the hopper, crushing chamber, blades, and screen can be easily removed and installed.

Product Features

The crusher is suitable for crushing and recycling PP, PE film and sheet materials, PET bottles and other products. Adopting a V-shaped knife holder design, the cutting working principle cuts the material into pieces instead of tearing it apart.

Durable Blades

V type blade design, blades are made of high-strength alloy tool steel, with high hardness, good abrasion resistance, and long durability.

Plastic Crusher Shredder Machine

Plastic shredders are machines that can break various types of plastic waste into smaller pieces for easy recycling.

Film Crusher Product Details

Our serves as a mature manufacturer of home lighting since 1992. The company takes up an area of 18,000, We enroll 1200 workers, consisting of the design team, R&D team, production team, and after-sales team.

Product Specifications

Our specialists can help you find the perfect seating for your home.

| Model No. | Crushing Chamber Dimension | Crushing Ability | Power | Rotate Speed | Mesh Size | Dimensions | Weight |

| TLV8350 | 830*500 | 300-900 | 30 | 600 | 25 | 1560*1640*2160 | 2000 |

| TLV1060 | 1030*600 | 450-1200 | 45 | 600 | 25 | 1900*1890*2650 | 2600 |

| TLV1265 | 1220*650 | 650-1500 | 55 | 600 | 25 | 2050*2250*2790 | 3000 |

| TLV1283 | 1220*830 | 800-2000 | 75 | 600 | 25 | 3000*2320*3250 | 6500 |

Video List

Video description.

FAQ

Tell us about your project requirements and we will figure out a solution that will meet your budget and design expectations.

Professional Service, Thoughtful Support

Serving customers worldwide with plastic crushing and recycling needs, Encycle Environmental always takes "sincere service to customers" as the driving force for its development, understanding customer needs in detail and providing customized machinery and equipment.